| Business |

| Desert in Bloom | |

|

|

|

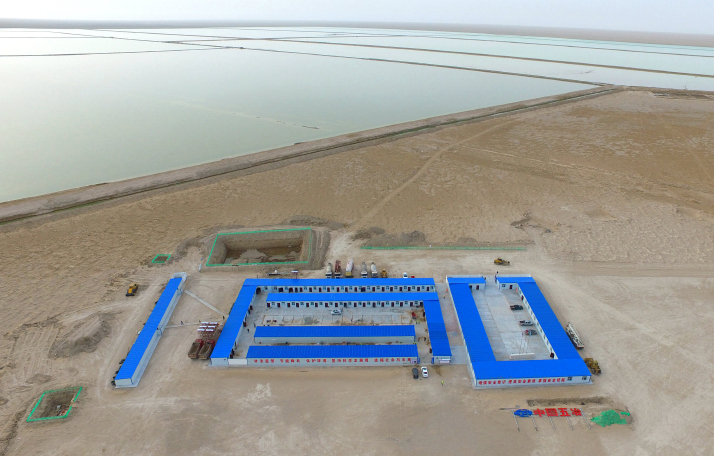

Inside the potassium processing plant (MCC)

Surrounded by boundless desert and buffeted by sandstorms, unfrozen at minus 20 degrees Celsius, a massive project quietly came into production in the Qaidam Basin of the Qinghai-Tibet Plateau on November 30. Designed to effectively utilize the lithium, boron and potassium resources of the Yiliping Salt Lake, the project is now running with an annual production capacity of 300,000 tons of potassium chloride, a chemical with multiple uses in agriculture, medicine and food production. This signifies the first successful major collaboration between the country's leading mining group, China Minmetals Corp. (CMC), and engineering procurement construction giant, the Metallurgical Corp. of China (MCC), since their strategic merger in 2015. An arduous task On February 24 this year, the China MCC5 Group Corp. Ltd., a member company of the MCC, won the bid for the Yiliping Salt Lake project, including the construction of the brine extraction equipment and transportation channels, as well as the contracts for potassium chloride production equipment, flooding control, water supply and other ancillary facilities. The MCC5 Group wasted no time in getting the project under way. The company sent out a team of engineers and technicians to Qinghai to mark out the extensive 117 km of water supply lines, and 57 km of electricity transmission lines necessary to make the project possible, whilst getting started on the production of the potassium processing equipment on site. After all, the construction would need to take place in the middle of an uninhabited desert.  The Yiliping Salt Lake project from above (MCC)

The Qaidam Basin is a hyper arid region in the Haixi Mongolian and Tibetan Autonomous Prefecture of northwest China's Qinghai Province. Of the 120,000 square km that make up this vast area, almost one quarter is covered by saline lakes, with the Qaidam Basin Desert accounting for another third. In recent years investment has been spurned by the discovery that the region is incredibly rich in natural resources, including significant quantities of asbestos, oil and natural gas. The basin also holds China's largest reserves of lithium, potassium, magnesium and sodium, a significant factor in the decision to construct a facility for the production of potassium chloride in such a remote and inhospitable environment. In terms of scale and complexity, it was no mean feat. The potassium processing equipment alone was to cover an area of nearly 900,000 square meters, made up of over 40 structures each contingent upon high engineering standards and complicated procedures for completion. The network of water supply lines, the longest in the MCC5 Group's history at 117 km, would need to pass through marshland, wetland, grassland and desert, en route to the complex, requiring the engineers and construction team to find innovative ways to design and build a system which could withstand the unique pressures of four different geographical environments. A whole new set of construction measures were thus needed in order to overcome the problems posed by landslides and sand drift. Yet in spite of these conditions, the MCC5 Group took a mere nine months to transform a design on paper into a functioning, modern industrial unit, further consolidating their reputation for rapid, efficient construction. The complex is focused on the development and extraction of the Yiliping Salt Lake's natural resources, and aims to expedite the formation of an industrial cluster for the exploration of lithium, potassium and boron. Plans are also in place to pilot a state-level recycling zone in the Qaidam Basin, with the hope of fueling economic development in Haixi. Unyielding commitment The intensity of the environment posed the greatest challenge to the MCC5 staff, and when the project began, water, power and phone service were unavailable on site. The team lacked access to fresh fruit and vegetables, whilst clean drinking water was scarce, and many workers struggled to contend with the difficulties posed by low levels of atmospheric oxygen at such a high altitude. Exploratory research for the water supply line required the team to undertake the challenge of navigating the terrain itself, unforgiving as it was unknown. There were occasions when personnel, upon encountering areas of marshland and quicksand impassable for their vehicles, had to leave their cars behind, walking tens of kilometers with instruments and equipment on their backs, their food and bottled water in hand. On other occasions the construction site was hit by sandstorms, the air becoming thick with clouds of sand, vision restricted and staff unable to even open their mouths. In such instances meals would often be contaminated by the invasive desert sands. To complicate an already grueling process, the extreme temperature variance between day and night meant that engineers and technicians worked in debilitating heat during the day before dressing up in thick cotton-padded jackets, shoes and hats once the sun had gone down. "I was among the first batch of employees sent to the project site, where we lived like a big family and bonded over the adversity facing us in the environment, all the while trying our utmost to complete the project according to schedule," said Liu Yang, a young engineer, whilst recalling his days at the project site. Zhang Jixiang, another member of the MCC5 staff, discovered that his neck was marked by numerous scars after work on the project had concluded. "Although they really hurt now, I couldn't feel the pain whilst caught up in all the different tasks taking place on site," said Zhang. Many workers recounted their fondness of the care packages regularly delivered by the company, which included canned fish, fruits and sunstroke prevention medicine, as well as winter clothes. Knowledge that their labors were being appreciated kept them going during long days and nights in the desert. Close cooperation Since the merger between the MCC and CMC in late 2015, internal reform has driven complete structural reorganization within the new conglomerate. Each link in the industrial chain, from resource exploration through design, construction, operation, circulation and processing, has been connected in a way which looks set to unlock the potential of a huge internal market. The Yiliping Salt Lake project serves to demonstrate the synergy generated by this process of amalgamation. The construction process was the result of close coordination between the MCC5 Group and the Minmetals Salt Lake Co. Ltd., the latter actively assisting the project team to decide on locations, transport material and communicate with the, albeit few, local residents whom they encountered in the wilderness. Throughout the duration of the project, company executives frequently visited the site to examine key operations such as brine extraction, power supply and potassium processing. The quality and efficiency demonstrated in the execution of the Yiliping project have not only earned the MCC5 Group widespread recognition across the industry, but also convinced the Minmetals Salt Lake Co. Ltd. of the merits of future collaboration. A pilot scheme targeting the production of lithium carbonate is now in the works, expected to have an annual production capacity of 200 tons. If it too is a success, then it will further enhance internal cooperation between the MCC and CMC, whilst tapping deeper still into an internal market worth hundreds of billions of yuan. Copyedited by Laurence Coulton Comments to dengyaqing@bjreview.com |

|

||||||||||||||||||||||||||||||

|